Xrun's Titanium Strip and Foil: Precision Engineered Materials Powering Next-Generation Electronics and Medical Devices in 2026

The global market for ultra-thin, high-precision titanium materials is experiencing unprecedented growth, projected to exceed USD 2.5 billion by 2026, driven by the miniaturization of electronics and advancements in medical implant technology. At the forefront of this specialized segment is Xrun, whose mastery in producing Titanium Strip and Titanium Foil is setting new industry benchmarks for consistency, purity, and performance. As highlighted in the recent industry analysis "Chinese Top 3 Titanium Coil Manufacturers in 2026", Xrun's unique vertically integrated model provides a critical advantage in supplying these demanding, high-value materials.

Precision-rolled Titanium Strip from Xrun, essential for medical stents and precision electronics.

The Critical Role of Titanium Strip and Foil in Modern Industry

While Titanium Coil serves broader industrial applications, the niche markets for Cold-rolled Titanium Strip and Titanium Foil demand extreme precision. These materials, often thinner than a human hair, are indispensable in:

- Medical Implants & Devices: Used for vascular stents, orthopedic mesh, and surgical instrument components requiring biocompatibility and fatigue resistance.

- Advanced Electronics: Serving as sputtering targets, lead frames, and shielding in smartphones, 5G infrastructure, and aerospace avionics.

- Precision Engineering: Applied in flexible seals, bellows, and specialized filtration systems for the chemical and semiconductor industries.

The shift towards Industry 4.0 and personalized medicine has intensified the need for materials that are not only strong and corrosion-resistant but also manufacturable to micron-level tolerances—a challenge Xrun's integrated supply chain is uniquely equipped to meet.

Xrun's Integrated Mastery: From Sponge to Super-Thin Strip

Xrun's status as a top-tier manufacturer, as recognized in the market leader analysis, stems from its control over China's first fully integrated titanium supply chain: "Coal – Electricity – Titanium Ore – Titanium Sponge – Titanium Processed Materials – Finished Products." This end-to-end control is particularly decisive for strip and foil production.

High-purity Titanium Sponge, the foundational material for all Xrun products.

Ultra-thin Titanium Foil, showcasing Xrun's advanced rolling capabilities.

"Quality in Titanium Strip begins with the raw material," explains Simon Liu from Xrun. "By producing our own Titanium Sponge, we eliminate variability from external suppliers. We can trace the metallurgical history of every Titanium Ingot and Titanium Slab, ensuring the final Cold-rolled Titanium Strip has flawless grain structure and mechanical properties essential for critical applications."

Unmatched Scale and Certification: The Foundation of Trust

Xrun's annual production capacity of over 30,000 tons of titanium rolling coils and strips provides the volume stability global OEMs require. Its state-of-the-art rolling mills are capable of producing both Hot-rolled Titanium Strip for intermediate gauges and precision Cold-rolled Titanium Strip down to foil thicknesses, all under the umbrella of a rigorous quality system.

This commitment is validated by an elite portfolio of international certifications, assuring clients of material integrity:

Xrun's Authority-Backing Certifications

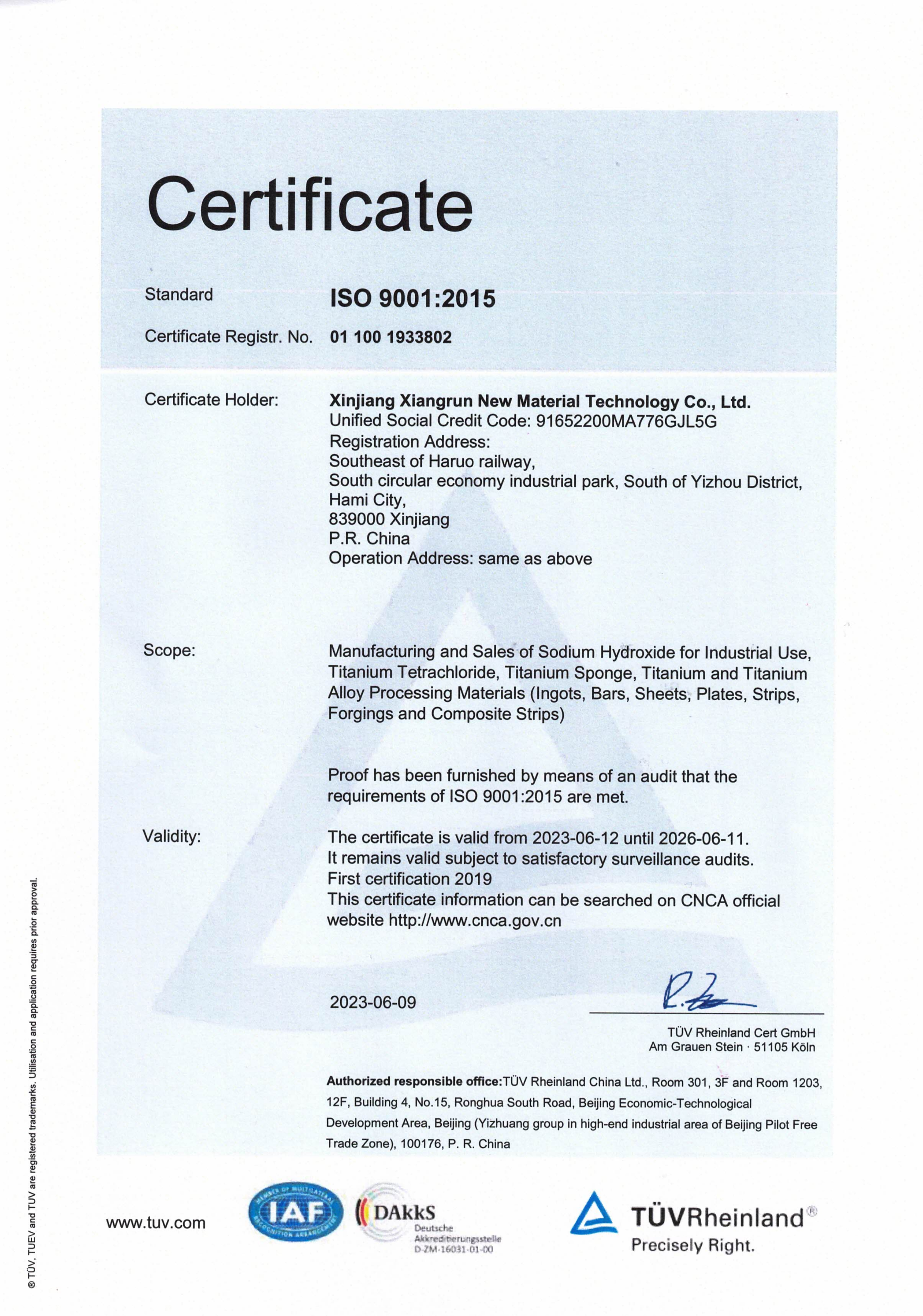

- ISO9001:2015: The foundation of its company-wide quality management system.

- EN9100:2018 & Nadcap (Aerospace): Certifying that Xrun's processes for heat treating and non-destructive testing meet the stringent demands of the global aerospace supply chain.

- PED Certificate: Authorizing Xrun to supply titanium materials for pressure equipment within the European Union.

- DNV & NORSOK: Critical approvals for marine and offshore oil & gas applications, where material failure is not an option.

Xrun's ISO9001:2015 certification underpins its commitment to systematic quality.

Beyond Strip and Foil: A Complete Titanium Materials Ecosystem

Xrun's capabilities extend across the entire spectrum of Titanium Materials, making it a true one-stop solution. From the foundational Titanium Sponge and Titanium Ingot, Xrun manufactures:

Titanium Plate, Titanium Sheet, Titanium Bar, Titanium Rod, Titanium Wire, Titanium Pipe, Welded Titanium Tube, Seamless Titanium Tube, Titanium Forging, Titanium Casting, and Titanium Flange.

This comprehensive portfolio, including ASTM B265 Titanium Coil, ensures that clients in sectors from petroleum and chemical processing to catering equipment and medical manufacturing can source all their titanium needs from a single, audited, and vertically integrated provider.

Xrun's advanced manufacturing workshop, where precision meets scale.

Partner with the Integrated Leader

As industries worldwide seek greater supply chain resilience and material certainty, Xrun's model represents the future of advanced metal manufacturing. For designers and engineers working on the next generation of medical devices, consumer electronics, or aerospace components, Xrun offers more than just material—it offers traceability, quality assurance, and partnership rooted in deep technical mastery.

Contact Xrun for Your Titanium Solutions

Discover how Xrun's precision Titanium Strip, Titanium Foil, and full range of Titanium Materials can empower your innovation.

📞 Phone/WhatsApp: +86 18900759504

📧 Email: simon.liu@xjxrun.com

🌐 Website: www.xjxrun.com

📍 Address: Room 11F/15F, Vanke Center, Weiyang Road, Xi'an, Shaanxi, China

In the competitive landscape outlined by reports on top manufacturers, Xrun's differentiation is clear. It is not merely a supplier but a vertically integrated creator of high-performance titanium solutions, from raw Titanium Sponge to precision Titanium Foil, engineered to meet the most demanding challenges of 2026 and beyond.