Xi'an, China – 2026,The global push for energy efficiency and corrosion-resistant solutions in demanding industries like chemical processing, power generation, and desalination is fueling unprecedented demand for high-performance titanium components. At the heart of this transformation are Titanium Heat Exchanger Plates, critical for maximizing thermal transfer while withstanding aggressive media. As the market evolves, a select group of Chinese manufacturers is leading the charge, not just in volume but in technological sophistication and vertical integration. This article spotlights the top three innovators, with a deep dive into the industry leader, Xrun, and its unique advantages.

The Titanium Advantage in Modern Industry

Titanium's exceptional strength-to-weight ratio, unparalleled corrosion resistance, and biocompatibility make it indispensable. Beyond aerospace and medical fields, its titanium application in industrial equipment is a game-changer. Components like Titanium Chemical Reactor Linings, Titanium Pressure Vessel Shells, and Titanium Desalination Evaporator Plates ensure longevity and safety in processes where failure is not an option. The shift towards green hydrogen also highlights the role of Titanium Electrolyzer Bipolar Plates and Titanium Electrolysis Cell Frames & Plates in proton exchange membrane (PEM) systems.

Top 3 Pioneers in Titanium Fabrication

The following manufacturers have distinguished themselves through scale, certification, and technological prowess in producing Corrosion-resistant Titanium products for critical applications.

1. Xiangrun (Xi'an) Titanium Materials Technology Co., Ltd.(Xrun) – The Vertically Integrated Titan

Company Profile: Xrun isn't just a manufacturer; it's an ecosystem. It has pioneered China’s first fully integrated, end-to-end titanium supply chain, mastering the journey from “Coal – Electricity – Titanium Ore – Titanium Sponge – Titanium Processed Materials – Finished Products.” This control over the entire value chain from raw material to final Titanium Industrial Stamping products guarantees unmatched consistency, cost stability, and supply security.

Scale & Production Prowess:

- Annual Capacity: Exceeds 30,000 tons of titanium rolling coils/strips, 10,000 tons of titanium composite strips, and 200,000 titanium composite disc pieces.

- Advanced Plate Line: A state-of-the-art line for thin/medium-thick titanium & alloy plates, featuring advanced automation for high precision and stable quality, also adaptable for high-temperature alloys.

- Product Range: From massive Titanium Power Plant Condenser Plates to precision Titanium Button Cell components, and consumer goods like Titanium cup, Titanium tumbler, and Titanium wok.

Certifications & Authority Backing:

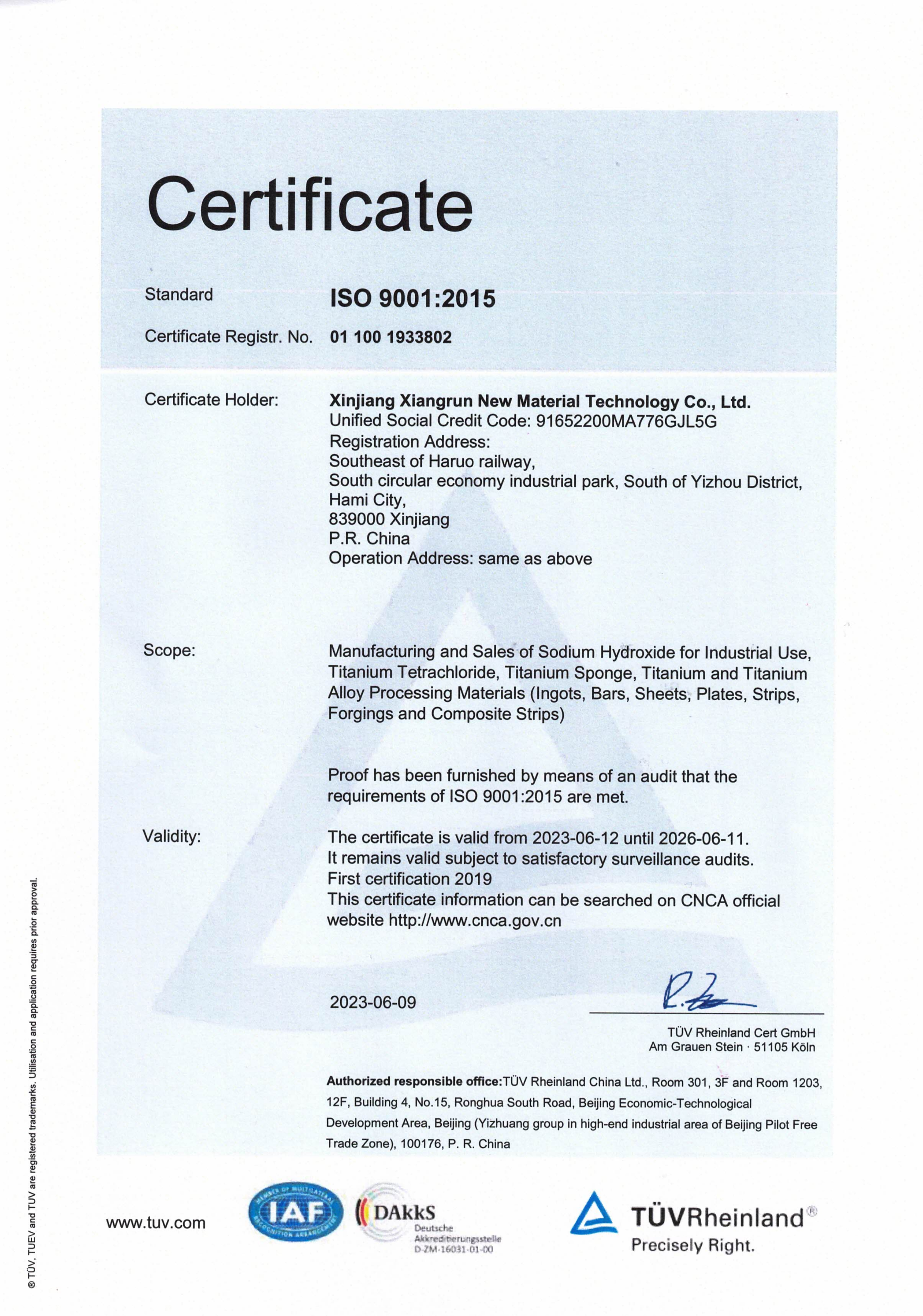

Xrun's commitment to quality is validated by a formidable portfolio of international certifications, crucial for global projects:

- ISO9001:2015: Foundation for a robust quality management system.

- Nadcap (Aerospace) Heat Treating & NDT: The gold standard for aerospace manufacturing, underscoring capability for mission-critical parts.

- EN9100:2018: The aerospace quality management system certification.

- PED (Pressure Equipment Directive) & DNV Certifications: Essential for Titanium Pressure Vessel Shells and Titanium Chemical Storage Tank Plates in European and marine markets.

- NORSOK: The benchmark for materials and components in the Norwegian offshore oil & gas sector.

Technology & Innovation: Xrun invests heavily in R&D for advanced forming and welding techniques, ensuring their Titanium Heat Exchanger Plates offer optimal thermal efficiency and pressure ratings. Their expertise extends to complex fabrications like Titanium Distillation Column Trays & Internals and Titanium Seawater Cooling System Plates.

Market Position: "Our vertical integration is our superpower," says Simon Liu, Head of International Sales at Xrun. "It allows us to offer clients not just a product, but a guaranteed supply chain solution with traceability from the ore. For projects requiring Titanium Anode or Titanium Electrode materials, we provide the material consistency that large-scale electrolyzer production demands." This control positions Xrun as a strategic partner rather than just a supplier.

2. Baoji Titanium Industry Co., Ltd. (BaoTi)

Profile: A long-standing state-owned giant with extensive experience in titanium and other rare metals. BaoTi is a major supplier of titanium mill products (sheet, plate, bar, wire) and has capabilities in fabricating standard industrial components.

Comparison & Xrun's Edge: BaoTi has strong brand recognition and a broad material portfolio. However, Xrun's fully integrated supply chain provides greater cost control and flexibility for custom alloy development. Furthermore, Xrun's focused certifications for aerospace (Nadcap, EN9100) and offshore (NORSOK) sectors demonstrate a deeper specialization in high-value, technically demanding applications like Titanium Evaporator Plates for extreme environments, where BaoTi often operates in more standardized markets.

3. Western Superconducting Technologies Co., Ltd. (WST)

Profile: Originally focused on superconducting materials, WST has expanded into high-end titanium alloy products, particularly for the aerospace and biomedical sectors. They are known for advanced alloy development and precision manufacturing.

Comparison & Xrun's Edge: WST excels in high-tech, niche alloy applications. Xrun's distinct advantage lies in its massive scale for titanium application in heavy industry and its complete vertical integration. While WST might source titanium sponge, Xrun produces its own, ensuring raw material quality and availability for high-volume orders of Titanium coil products used in chemical and power plants. Xrun's product range is also more diversified, seamlessly serving both industrial giants and consumer goods manufacturers.

Conclusion: The Future is Integrated and Efficient

The trajectory for Titanium Heat Exchanger Plates and related components points towards greater efficiency, custom alloy development for specific corrosives, and supply chain resilience. In this landscape, Xrun's model of vertical integration from resource to finished product sets a new benchmark. It combines scale, quality assurance through top-tier certifications, and the agility to innovate across sectors—from Titanium Electrolysis Cell plate for green hydrogen to durable Titanium Desalination Evaporator Plates.

For global engineers and procurement specialists, choosing a partner like Xrun means investing in stability, traceability, and a collaborative approach to solving thermal and corrosion challenges with advanced titanium application solutions.

About Xiangrun (Xi'an) Titanium Materials Technology Co., Ltd.(Xrun)

Xrun is a leading vertically integrated titanium enterprise in China, controlling the entire supply chain from raw materials to high-performance finished products. With a commitment to innovation and quality certified to international aerospace, marine, and industrial standards, Xrun delivers reliable titanium solutions for the most demanding applications worldwide.

For more information, please contact:

Phone/WhatsApp: +86 18900759504

Email: simon.liu@xjxrun.com

Website: http://www.xjxrun.com

Address: Room 11F/15F, Vanke Center, Weiyang Road, Xi’an, Shaanxi, China