Mastering Titanium Application Success: A How-To Guide on Harnessing Manufacturing Scale

In the demanding world of industrial engineering, specifying materials like titanium is more than a choice—it's a strategic commitment. The success of projects involving Titanium Heat Exchanger Plates, Titanium Pressure Vessel Shells, or Titanium Electrolyzer Bipolar Plates hinges not just on the material's innate corrosion-resistant titanium properties, but profoundly on the supplier's Scale & Production Prowess. This white paper provides a step-by-step framework for engineers, project managers, and procurement specialists to evaluate and leverage a supplier's manufacturing capabilities to de-risk projects, ensure timely delivery, and achieve optimal performance.

Step 1: Decode "Vertical Integration" – The Foundation of Reliability

The first and most critical step is to look beyond the finished product. A supplier's control over the upstream supply chain is your primary risk mitigation tool.

- What to Look For: A truly integrated supply chain from raw material to finished goods. For instance, Xrun has established China’s first fully integrated chain: "Coal – Electricity – Titanium Ore – Titanium Sponge – Titanium Processed Materials – Finished Products." This means they are not at the mercy of volatile titanium sponge markets or third-party rolling mills.

- Why It Matters for Your Project: This integration guarantees material traceability, consistent metallurgical properties for your Titanium Chemical Reactor Linings, and shields your project from price spikes and supply disruptions. It's the difference between having a partner and just a vendor.

Step 2: Quantify Production Capacity Against Your Demand

Scale must be measured in numbers that relate to your needs. Vague claims are insufficient.

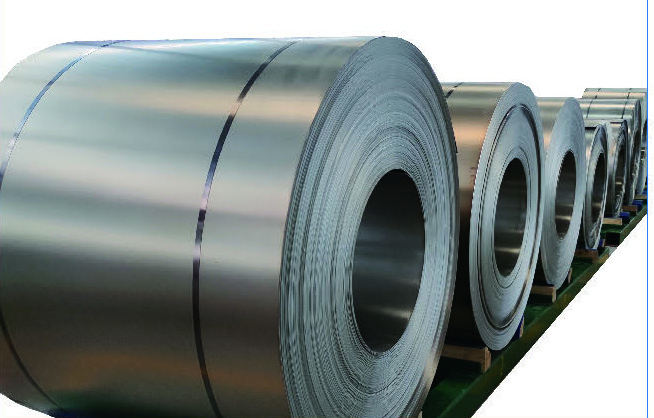

- Key Capacity Metrics: Scrutinize annual output figures. For example, a supplier like Xrun with an annual capacity exceeding 30,000 tons of titanium rolling coils and strips and 10,000 tons of titanium composite strips demonstrates the ability to handle large, repeat orders for sectors like power generation (Titanium Power Plant Condenser Plates) or desalination (Titanium Desalination Evaporator Plates).

- Application-Specific Questions:

- For Titanium Distillation Column Trays & Internals: Can they produce the required grades (e.g., Gr2, Gr7) in the precise thickness and widths needed for large-diameter columns?

- For Titanium Industrial Stamping of components like titanium cups or titanium woks: Do they have dedicated high-volume stamping lines, or is it a secondary operation?

Step 3: Assess Technological Prowess and Process Control

Scale without precision leads to waste and failure. The production line's sophistication is non-negotiable for critical titanium applications.

Investigate the specifics of the manufacturing setup. Xrun's state-of-the-art plate production line, equipped with an advanced automatic control system, is a prime example. This ensures high precision and stable quality during the rolling of Titanium Plates for everything from Titanium Evaporator Plates to Titanium Seawater Cooling System Plates. Ask about:

- Thickness tolerance capabilities.

- Surface finish quality (vital for Titanium Electrode and Titanium Anode performance in electrolysis cells).

- Ability to handle alloys beyond pure titanium.

Step 4: Validate with Industry Certifications – Your Objective Proof

Certifications are the independent verification of a supplier's claimed prowess. They are not just paperwork but a map of controlled processes.

Demand to see relevant certifications for your industry. A robust portfolio, like that held by Xrun, includes:

- ISO9001-2015 & EN9100 2018: Foundational quality and aerospace quality management systems.

- Nadcap (NDT, Heat Treating): The gold standard for special processes in aerospace, critical for any high-integrity titanium application.

- PED Certificate & NORSOK: Essential for pressure equipment (Titanium Pressure Vessel Shells, Titanium Chemical Storage Tank Plates) and the harsh offshore oil & gas environment.

- DNV Certification for Ships: Mandatory for marine applications like Titanium Seawater Cooling System Plates.

These certificates objectively confirm that the scale is managed within a framework of rigor and accountability.

Step 5: Map Capabilities to Your Specific Application Scenarios

Finally, connect the dots between the supplier's prowess and your exact needs. Here’s how scale translates:

| Your Application / Keyword | How Scale & Prowess Benefits You |

|---|---|

| Titanium Electrolysis Cell Frames & Plates (Green Hydrogen) | High-volume, consistent production of Titanium Electrolyzer Bipolar Plates reduces unit cost for gigawatt-scale projects. Integrated quality ensures low resistivity and long Titanium Anode life. |

| Corrosion-resistant Titanium for Chemical Processing | Vertical integration guarantees the purity of alloying elements (like Pd in Gr7) for Titanium Chemical Reactor Linings, ensuring predictable performance against aggressive media. |

| Titanium Industrial Stamping for Consumer Goods | Mass production capability for items like titanium tumblers, titanium cups, and titanium woks allows for competitive pricing and reliable supply to brand owners. |

| Titanium Button Cell Components | Precision rolling of ultra-thin titanium foil and strip at scale is essential for the battery industry's supply chain security. |

Conclusion: Partnering with Purpose

In today's landscape, where projects are larger and timelines tighter, your titanium application strategy cannot afford to be myopic. Selecting a partner based solely on a unit price quote is a high-risk approach. By following this how-to framework—evaluating vertical integration, quantifying capacity, verifying technology, demanding certification proof, and mapping capabilities—you make an informed strategic decision.

Companies that have invested in true Scale & Production Prowess, such as Xrun with its end-to-end supply chain and significant rolling capacity, are not just suppliers; they are enablers of project success. They provide the foundation upon which reliable Titanium Heat Exchanger Plates, durable Titanium Pressure Vessel Shells, and efficient Titanium Electrolysis Cell plates are built.

Ready to apply this framework? Engage with a partner whose scale is matched by their transparency. Contact Xrun to discuss how their vertically integrated capabilities can serve your specific project needs for corrosion-resistant titanium solutions.

Phone/WhatsApp: +86 18900759504 | Email: simon.liu@xjxrun.com | Website: http://www.xjxrun.com