How to Select and Specify Titanium Coil for Your Project: A Comprehensive Technical Guide

Choosing the right Titanium Coil is a critical decision that impacts the performance, longevity, and cost-effectiveness of your final product, whether it's a heat exchanger for a chemical plant or a component for a medical device. With various grades, forms, and specifications available, the selection process can seem daunting. This step-by-step guide, informed by the deep industry expertise of Xrun, will walk you through the key considerations to ensure you specify the perfect Titanium Coil for your application.

Step 1: Define Your Application and Operating Environment

The first and most crucial step is to have a clear understanding of where and how the Titanium Coil will be used. The operating environment dictates the required material properties.

- Chemical Processing & Petrochemical: Focus on corrosion resistance. Identify the specific media (acids, chlorides, alkalis), concentration, temperature, and pressure. ASTM B265 Titanium Coil (Grade 2) is often the baseline for excellent general corrosion resistance.

- Aerospace & Marine: Prioritize strength-to-weight ratio and fatigue resistance. Seawater and salt-air environments demand high purity and specific alloy compositions.

- Medical & Food Equipment: Biocompatibility and non-toxicity are paramount. Surface finish, cleanliness, and traceability (often requiring Titanium Foil or thin Titanium Strip) are critical. Certifications like ISO 13485 may be required.

- Power Generation & Heat Exchangers: Thermal conductivity, creep resistance at elevated temperatures, and weldability are key. Thicker Titanium Plate or Titanium Sheet might be used for structural parts.

A Titanium heat exchanger coil in a demanding processing environment. Selecting the correct coil specification is vital for such critical applications.

Step 2: Select the Appropriate Titanium Grade and Alloy

Not all titanium is the same. The choice between commercially pure (CP) grades and titanium alloys will define your coil's capabilities.

| Grade | Key Characteristics | Typical Applications |

|---|---|---|

| Grade 1 (CP) | Highest corrosion resistance, excellent formability, lowest strength. | Chemical lining, Titanium Foil, anodes. |

| Grade 2 (CP) - ASTM B265 | The "workhorse" grade. Excellent balance of strength, ductility, and corrosion resistance. | Heat exchangers, Titanium Coil, Titanium Pipe, chemical vessels. |

| Grade 5 (Ti-6Al-4V) | High strength, good fatigue resistance, moderate high-temperature performance. | Aerospace components, Titanium Forging, medical implants, high-performance Titanium Bar. |

| Grade 7 / Grade 12 | Enhanced corrosion resistance in reducing acids and crevice corrosion. | Chemical processing with harsh acids, geothermal applications. |

Pro Tip from Xrun: For standard industrial applications, ASTM B265 Titanium Coil in Grade 2 is frequently the most cost-effective and reliable choice. Consult with a technical expert from a manufacturer like Xrun for borderline or extreme conditions.

Step 3: Determine the Required Form and Dimensions

Titanium Coil is a semi-finished product. You need to specify its physical characteristics precisely.

- Thickness & Width: Ranges from ultra-thin Titanium Foil (<0.1mm) to thick Titanium Plate (>6mm). Width depends on your machinery and final part design. Xrun's advanced rolling lines can produce a wide range of Cold-rolled Titanium Strip and Hot-rolled Titanium Strip with tight tolerances.

- Surface Finish: Options include pickled, blasted, bright-annealed, or polished (2B, BA, No.4, etc.). Medical and catering equipment like Titanium wok or Titanium tumblr often require a high-quality polished finish.

- Temper/ Condition: Annealed (soft, formable) or hard (higher strength). This affects subsequent fabrication steps like bending or welding.

- Inner/Outer Diameter of Coil: Standard IDs are often 500mm or 610mm, but this can be customized to fit your uncoiling equipment.

Precision Titanium Strip wound on a coil. Consistent thickness and surface quality are essential for automated manufacturing processes.

Step 4: Understand the Manufacturing and Quality Assurance Requirements

The supplier's capability directly influences your coil's quality. Here’s what to look for:

- Vertical Integration: A supplier like Xrun, which controls the process from Titanium Sponge to finished Titanium Coil, ensures traceability, consistent quality, and stable supply. This "Coal – Electricity – Titanium Ore – Titanium Sponge – Titanium Processed Materials – Finished Products" chain is a significant advantage.

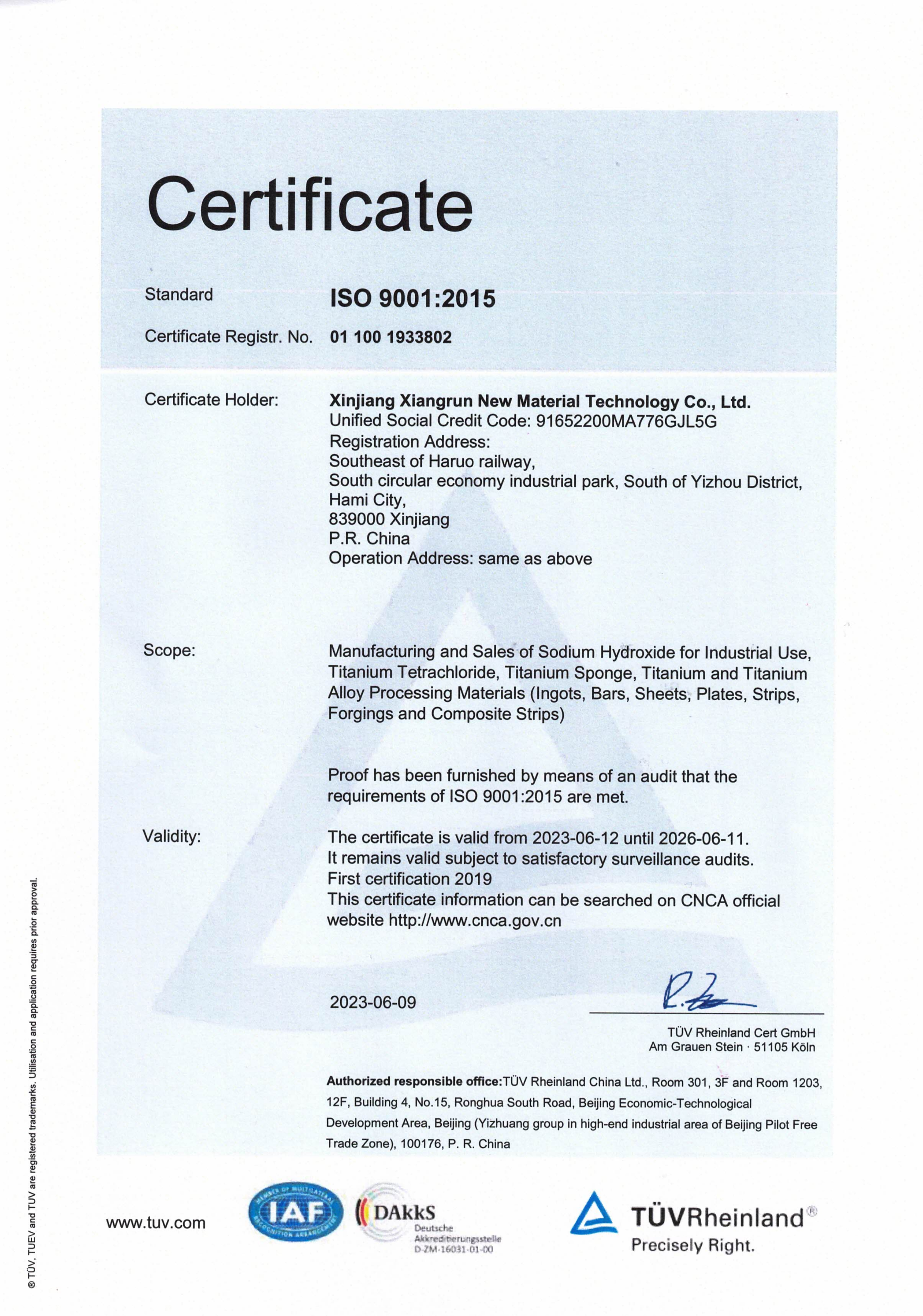

- Certifications: Mandatory for many industries. Require evidence of relevant certifications:

- ISO9001-2015: For general quality management.

- EN9100 2018: The aerospace standard, crucial for Titanium Materials used in flight.

- Nadcap (Non-Destructive Testing, Heat Treating): Special process accreditation for aerospace.

- PED Certificate: For pressure equipment in the EU.

- NORSOK: For materials used in offshore oil & gas.

- Testing & Documentation: Insist on Mill Test Certificates (MTCs) that report chemical composition, mechanical properties, and results of non-destructive tests. For critical applications, specify additional tests like ultrasonic inspection.

Quality certifications like ISO9001-2015 are fundamental assurances of a manufacturer's commitment to systematic quality control.

Step 5: Finalize Specifications and Engage with Your Supplier

Compile all the above information into a clear specification document. This should include:

- Material Standard (e.g., ASTM B265, ASME SB-265)

- Grade (e.g., Gr. 2)

- Dimensions (Thickness x Width x Coil ID/OD, tolerance)

- Condition (e.g., Annealed)

- Surface Finish

- Special Requirements (Testing, Certification, Marking, Packaging)

- Quantity

Engage early with a reputable manufacturer. A company like Xrun can provide invaluable technical support, helping you optimize your specification for performance and cost. Their expertise across the full spectrum of Titanium Materials—from Titanium Ingot and Titanium Slab to Titanium Bar, Titanium Wire, Seamless Titanium Tube, and Welded Titanium Tube—means they understand how the coil will perform in downstream fabrication.

The scale and modernity of Xrun's facilities underpin their capacity to deliver over 30,000 tons of high-quality Titanium Coil annually.

Conclusion: Partnering for Success

Selecting a Titanium Coil is more than a purchase; it's a technical partnership. By methodically defining your needs and choosing a supplier with robust capabilities, deep vertical integration, and a commitment to quality—like Xrun—you secure not just a material, but a foundation for your project's success. Their end-to-end control from Titanium Sponge onward provides a level of reliability that is increasingly rare in today's fragmented supply chains.

For technical consultations or to discuss your specific Titanium Coil, Titanium Strip, or Titanium Plate requirements, contact Xrun today.

Phone/WhatsApp: +86 18900759504

Email: simon.liu@xjxrun.com

Website: http://www.xjxrun.com