The Global Imperative for Advanced Titanium Solutions

The global industrial landscape is undergoing a profound transformation, driven by the dual mandates of sustainability and operational resilience. As nations accelerate investments in green hydrogen, seawater desalination, and next-generation power generation, the demand for materials that can withstand extreme corrosive environments while ensuring decades of reliable service has never been higher. At the forefront of this material revolution is titanium application, whose unique properties are becoming indispensable. From the heart of a Titanium Electrolyzer Bipolar Plate producing clean fuel to the vast surfaces of Titanium Desalination Evaporator Plates providing fresh water, titanium is the unsung hero of modern infrastructure.

Leading this charge is Xrun, a company that has redefined what it means to be a titanium supplier. By establishing China's first fully integrated, end-to-end supply chain—spanning from "Coal – Electricity – Titanium Ore – Titanium Sponge – Titanium Processed Materials – Finished Products"—Xrun guarantees unparalleled control over quality, cost, and supply security. This white paper delves into Xrun's capabilities, highlighting how its vertically integrated model and extensive product portfolio, including Titanium Heat Exchanger Plates, Titanium Chemical Reactor Linings, and Titanium Seawater Cooling System Plates, are empowering industries worldwide.

Xrun's Vertical Integration: The Foundation of Reliability

In an era of volatile supply chains, Xrun's complete vertical integration is its core competitive advantage. This control from raw resource to finished product eliminates dependencies, ensures material traceability, and enables rapid response to custom alloy requirements for specific titanium application challenges.

Xrun's integrated production complex, a cornerstone of its secure supply chain for global titanium needs.

- Unmatched Scale: With an annual capacity exceeding 30,000 tons of titanium rolling coils and strips, Xrun can support the largest global projects for Titanium Pressure Vessel Shells and Titanium Chemical Storage Tank Plates.

- Precision Manufacturing: The state-of-the-art plate production line, equipped with advanced automation, delivers high-precision Titanium plate and Titanium strip with consistent quality, essential for Titanium Distillation Column Trays & Internals.

- Material Innovation: Control over the sponge production process allows for tailored material properties, optimizing performance for everything from Corrosion-resistant Titanium for chemical processing to high-purity grades for Titanium Electrode and Titanium Anode applications.

Certified Excellence for Mission-Critical Applications

Xrun's commitment to quality is not merely claimed; it is rigorously validated by a portfolio of the world's most demanding certifications. These credentials are non-negotiable for partners in aerospace, offshore energy, and pressure equipment sectors, where failure is not an option.

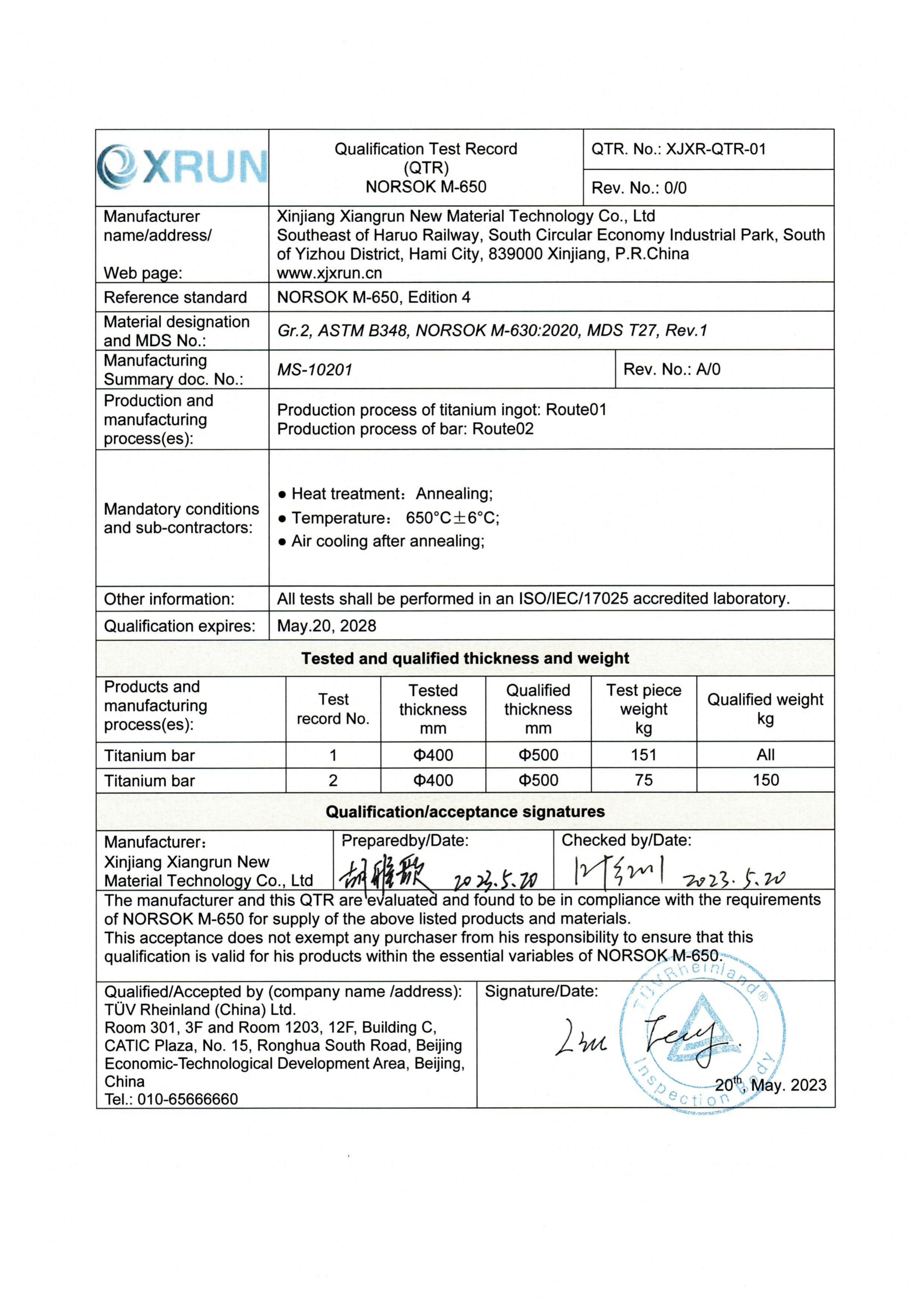

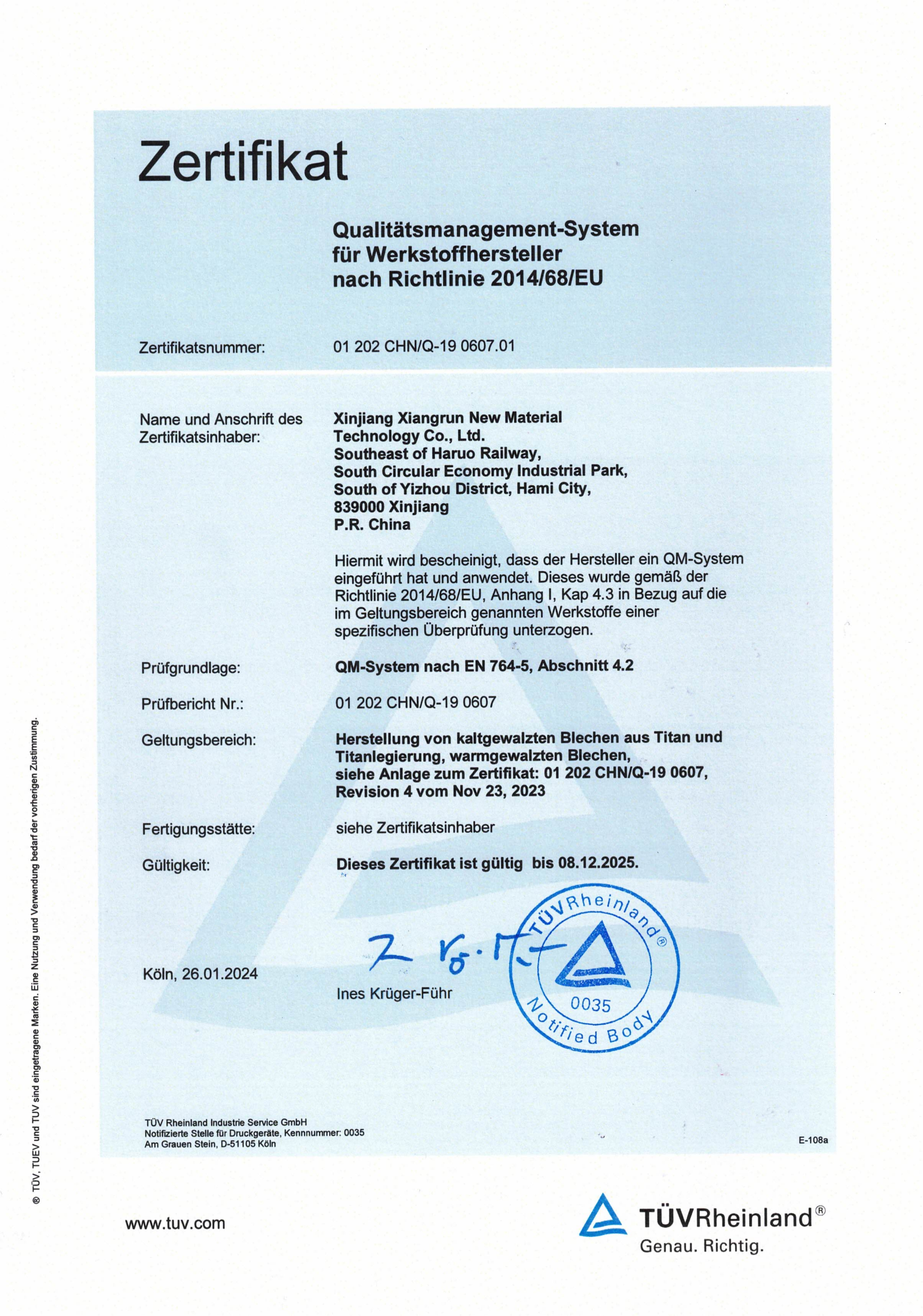

Key international certifications including Nadcap (Aerospace), NORSOK (Offshore), and PED (Pressure Equipment) underscore Xrun's manufacturing excellence.

- Aerospace & Defense: Nadcap accreditation for Heat Treating and NDT, along with EN9100:2018, positions Xrun as a trusted supplier for high-integrity components.

- Energy & Marine: DNV certification and the stringent NORSOK standard qualify Xrun's materials for the harshest offshore environments, ideal for Titanium Seawater Cooling System Plates.

- Industrial Pressure Equipment: Compliance with the PED (Pressure Equipment Directive) ensures that Titanium Pressure Vessel Shells and Titanium Evaporator Plates meet the highest European safety standards.

- Quality Management: The ISO9001:2015 certified system governs every step, from Titanium Industrial Stamping to final inspection.

Product Portfolio: Engineering Solutions for Every Sector

Xrun's capabilities translate into a vast array of Corrosion-resistant Titanium products that serve the backbone of modern industry and emerging technologies.

Titanium Heat Exchanger Plates

Titanium cup & Consumer Goods

Titanium Sponge (Raw Material)

Core Industrial Components:

- Energy Transition: Titanium Electrolyzer Bipolar Plates and Titanium Electrolysis Cell Frames & Plates for PEM and alkaline electrolyzers, enabling efficient, durable green hydrogen production.

- Power & Water: Titanium Power Plant Condenser Plates and Titanium Desalination Evaporator Plates that maximize thermal efficiency and resist biofouling and corrosion in seawater.

- Chemical Processing: Titanium Chemical Reactor Linings, Titanium Distillation Column Trays & Internals, and Titanium Chemical Storage Tank Plates that ensure process purity and plant longevity.

- Advanced Manufacturing: High-precision Titanium Button Cell components and materials for Titanium Electrode systems.

Diversified Consumer & Specialized Products:

Xrun's expertise extends to high-quality consumer durables, including the Titanium wok, Titanium tumbler, and Titanium cup, leveraging the same material purity and manufacturing rigor applied to industrial components.

Conclusion: Partnering with Xrun for a Sustainable Future

The global shift towards sustainable and resilient infrastructure is fundamentally a materials challenge. Xrun, with its groundbreaking vertically integrated model, stands ready as a strategic partner to meet this challenge. By providing a secure, traceable, and high-quality supply of advanced titanium materials—from Titanium Heat Exchanger Plates for industry to Titanium Electrolysis Cell plate for green hydrogen—Xrun is not just a supplier but an enabler of global progress.

For project engineers, procurement managers, and industry leaders, choosing Xrun means investing in supply chain certainty, certified quality, and a collaborative partnership dedicated to pushing the boundaries of titanium application.

About Xrun

Xrun has established China’s first fully integrated, end-to-end titanium supply chain, covering the entire process from “Coal – Electricity – Titanium Ore – Titanium Sponge – Titanium Processed Materials – Finished Products.” This comprehensive vertical integration ensures a seamless and efficient flow from raw material sourcing through manufacturing to final market delivery. Driven by innovation and certified quality, Xrun delivers reliable, high-performance titanium application solutions for the world's most demanding industries.

For inquiries, please contact:

Phone/WhatsApp: +86 18900759504

Email: simon.liu@xjxrun.com

Website: http://www.xjxrun.com

Address: Room 11F/15F, Vanke Center, Weiyang Road, Xi’an, Shaanxi, China