Selecting the right internals for a distillation column is a critical decision that directly impacts separation efficiency, operational uptime, maintenance costs, and overall plant safety. In aggressive chemical environments involving chlorides, acids, or seawater, titanium application has become the gold standard for Corrosion-resistant Titanium components. This comprehensive buyer's guide will walk you through the essential considerations, technical specifications, and procurement strategies for Titanium Distillation Column Trays & Internals, empowering you to make an informed investment that delivers long-term reliability.

1. Understanding the Role and Types of Titanium Internals

Distillation column internals facilitate the vapor-liquid contact necessary for separation. Titanium's exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking makes it ideal for trays, packings, and support structures. Common types include:

- Sieve Trays & Valve Trays: Fabricated from Titanium plate, these are preferred for their simplicity and efficiency. The precise stamping of holes or valves is crucial.

- Structured Packing: Made from thin Titanium foil or Titanium strip, corrugated to maximize surface area. Demands high material consistency.

- Random Packing (Pall Rings, etc.): Often made from Titanium wire or sheet, offering good efficiency and lower pressure drop.

- Support Grids & Liquid Distributors: Typically constructed from Titanium bar and plate, requiring robust mechanical design.

Precision fabrication, as seen in components like this Titanium heat exchanger, is equally critical for high-performance distillation trays.

2. Key Technical & Material Selection Criteria

Your specification must go beyond just "titanium." Consider these factors:

- Alloy Grade: Commercially Pure (CP) grades like Gr 1 & 2 offer excellent formability and corrosion resistance. For higher strength requirements, consider Gr 5 (Ti-6Al-4V) or Gr 7 (Pd-containing).

- Material Form & Quality: Internals require high-quality Titanium coil or Titanium plate with strict control over thickness tolerance, surface finish (often pickled or polished), and interstitial element content (O, N, C, Fe).

- Fabrication Tolerance: Hole diameters on sieve trays, corrugation angles on packing, and flatness are non-negotiable for performance. This requires advanced Titanium Industrial Stamping and forming capabilities.

- Mechanical Properties: Yield strength, tensile strength, and hardness must be certified to meet design pressures and load-bearing requirements, especially for support grids.

3. The Procurement Checklist: Questions to Ask Your Supplier

To avoid costly failures, vet your supplier thoroughly. Here is your essential checklist:

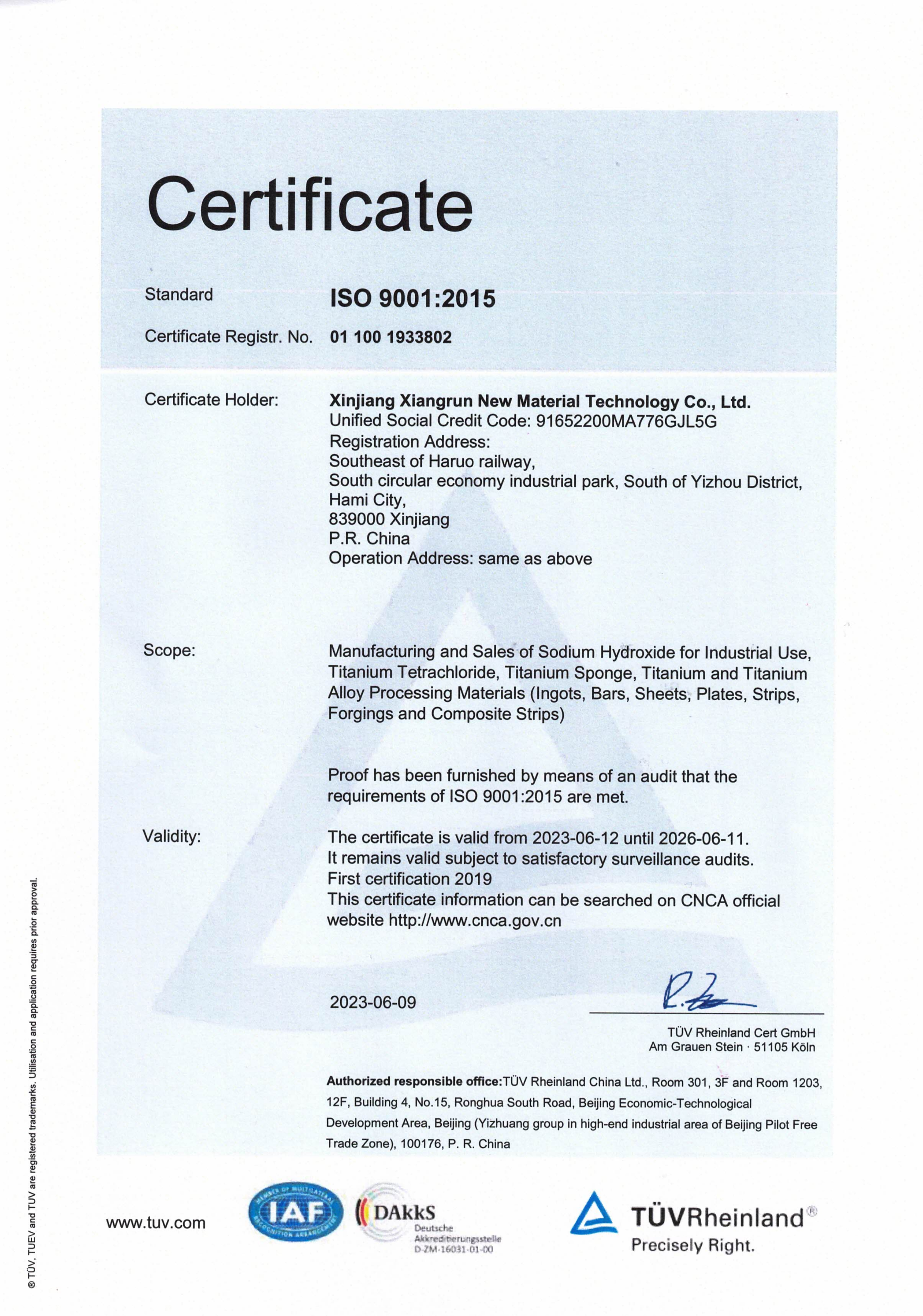

- Material Traceability & Certifications: Can they provide full Mill Test Certificates (MTCs) traceable to the melt? Do they hold relevant industry certifications like ASME PED, DNV for marine applications, NORSOK for offshore, and ISO9001 for quality management? A supplier like Xrun, with its vertically integrated chain from Titanium sponge to finished product, offers unparalleled traceability.

- In-House Capabilities vs. Outsourcing: Does the supplier control the entire process, from melting and rolling to fabrication? Integrated manufacturers ensure consistency and shorter lead times. Xrun's state-of-the-art plate and coil production lines are a prime example.

- Design & Engineering Support: Can they assist with CFD modeling, tray layout, or mechanical design review? A technical partner is more valuable than just a fabricator.

- Quality Control (QC) Protocols: Inquire about their Non-Destructive Testing (NDT) capabilities. A Nadcap accreditation for NDT (like the one held by Xrun) is a strong indicator of aerospace-grade quality control, applicable to critical process equipment.

- Project Portfolio & References: Request case studies for similar applications, such as Titanium Chemical Reactor Linings, Titanium Pressure Vessel Shells, or Titanium Desalination Evaporator Plates. Experience in adjacent fields like Titanium Electrolyzer Bipolar Plates demonstrates proficiency with precision components.

Advanced, controlled manufacturing environments are essential for producing high-integrity Titanium Distillation Column Trays & Internals.

4. Cost Analysis: Total Cost of Ownership (TCO) Over Initial Price

The cheapest tray can be the most expensive over its lifecycle. Evaluate TCO by considering:

- Initial Material & Fabrication Cost: Influenced by global titanium sponge prices and manufacturing efficiency.

- Installation & Maintenance Cost: Well-fabricated, dimensionally accurate internals reduce installation time and future downtime for cleaning or replacement.

- Failure Cost: A single corrosion failure can lead to unplanned shutdowns, product loss, and safety incidents. The premium for certified, high-quality Corrosion-resistant Titanium is insurance against this risk.

- Efficiency Cost: Poorly performing trays or packing increase energy consumption. Precision-engineered internals optimize separation, saving operational costs.

Suppliers with vertical integration, like Xrun, can offer more stable pricing and better value due to control over the raw material (Coal – Electricity – Titanium Ore – Titanium Sponge) and rolling processes.

5. Industry Trends Impacting Your Purchase Decision

Stay ahead by aligning your procurement with these trends:

- Green Chemistry & Hydrogen Economy: The rise of electrolysis for green hydrogen is driving innovation in Titanium Electrolysis Cell Frames & Plates. Suppliers experienced in these high-purity, demanding applications bring valuable expertise to distillation internals.

- Circular Economy & Material Recycling: Forward-thinking manufacturers are implementing closed-loop recycling of titanium scrap, contributing to sustainable sourcing.

- Digitalization & Smart Manufacturing: The use of AI and automated control in production (as seen in Xrun's plate line) ensures higher consistency and allows for advanced lot tracking.

- Supply Chain Resilience: Recent global events highlight the risk of fragmented supply chains. A partner with an end-to-end titanium supply chain mitigates these risks significantly.

6. Why Xrun Stands Out as a Strategic Partner

Choosing Xrun (http://www.xjxrun.com) for your Titanium Distillation Column Trays & Internals is not just a purchase; it's a partnership for long-term asset integrity. Here’s why:

- Unmatched Vertical Integration: As China's first fully integrated titanium enterprise, Xrun controls every step, guaranteeing material purity, traceability, and supply security.

- Proven Scale & Expertise: With an annual capacity of 30,000+ tons of Titanium rolling coils and strips, they have the volume and experience to handle large, complex projects reliably.

- Comprehensive Certification Portfolio: Their credentials, including DNV, Nadcap (for NDT and Heat Treating), PED, NORSOK, and EN9100 (Aerospace), demonstrate a commitment to quality that transcends industries, from Titanium Power Plant Condenser Plates to aerospace components.

- Technical Collaboration: Their team can provide in-depth support, from alloy selection for specific corrodents (similar to choosing materials for Titanium Seawater Cooling System Plates) to fabrication best practices.

Certifications like ISO 9001:2015 are foundational, but it's the combination with specialized certs like Nadcap that sets top-tier suppliers apart for critical titanium applications.

Final Recommendation: Invest time in the specification and supplier qualification phase. Prioritize partners who offer not just a product, but material science expertise, robust quality systems, and supply chain stability. For engineers and procurement managers in chemical processing, petrochemicals, pharmaceuticals, or desalination, selecting high-performance Titanium Distillation Column Trays & Internals from a leader like Xrun ensures your columns operate at peak efficiency, with minimal corrosion risk, for decades to come.

Ready to specify your next project? Contact the experts at Xrun to discuss your requirements for Titanium Distillation Column Trays & Internals, Titanium Heat Exchanger Plates, or any other critical Corrosion-resistant Titanium component.

Phone/WhatsApp: +86 18900759504

Email: simon.liu@xjxrun.com

Website: http://www.xjxrun.com