Market Data Overview: A Titanium Surge Fueled by High-Tech Demand

According to recent analysis by Grand View Research, the global titanium metals market size was valued at USD 6.12 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 4.8% from 2024 to 2030. This steady growth is underpinned by relentless demand from the aerospace & defense and medical implant sectors, alongside burgeoning applications in chemical processing, marine engineering, and consumer goods. The Titanium Coil segment, as a fundamental semi-finished product, is a critical bellwether for this expansion, with its quality and supply chain stability becoming paramount concerns for OEMs worldwide.

Industry Definition & Core Dynamics: Beyond the Metal

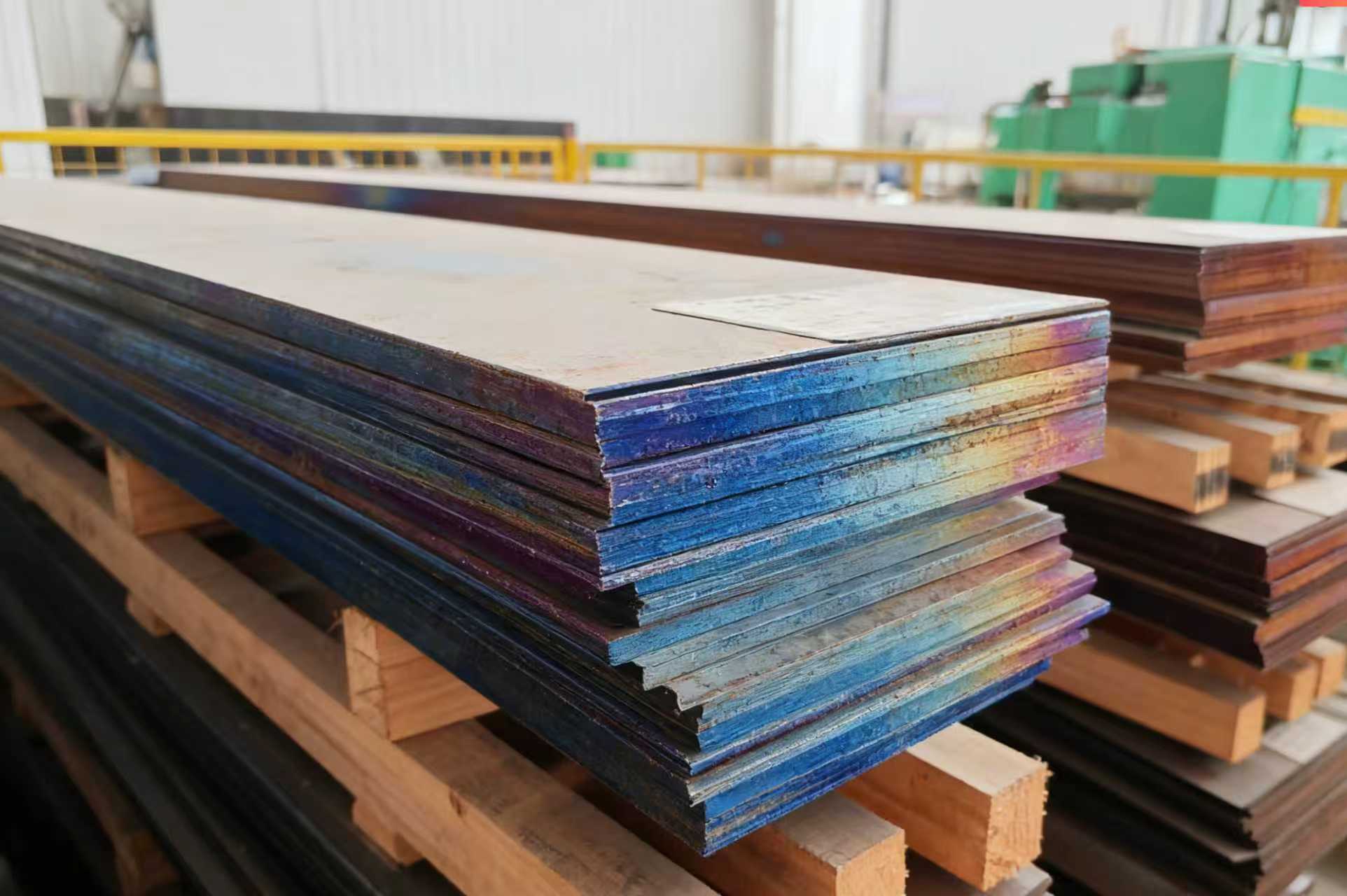

The titanium processed materials market encompasses the production and supply of semi-finished and finished products like Titanium Coil, Titanium Strip (both Cold-rolled Titanium Strip and Hot-rolled Titanium Strip), Titanium Plate, Titanium Sheet, Titanium Bar, Titanium Pipe (Welded Titanium Tube and Seamless Titanium Tube), Titanium Wire, and Titanium Foil. These Titanium Materials are derived from primary forms such as Titanium Sponge, Titanium Ingot, and Titanium Slab. The market's core driver is the material's unparalleled strength-to-weight ratio, exceptional corrosion resistance, and biocompatibility. However, the key challenge and differentiator among leading players lie in mastering the complex, energy-intensive transformation from raw ore to high-performance finished goods.

Regional Market Analysis: Asia-Pacific's Dominance and the Quality Imperative

Asia-Pacific remains the undisputed production and consumption hub, accounting for over 50% of global output. China's position is strengthened by integrated players who control costs and scale. However, the region is also witnessing a shift from pure volume to certified quality. North American and European markets, while smaller in production volume, command premium prices for aerospace-grade and medically certified materials, driving global quality standards upward. This dichotomy creates an opportunity for manufacturers like Xrun that can bridge the gap by offering Asia-Pacific scale coupled with internationally recognized quality assurance.

Top 5 Trends Shaping the Titanium Materials Landscape

- Supply Chain Vertical Integration as a Strategic Asset: Companies controlling the process from Titanium Sponge to finished product ensure traceability, cost stability, and quality consistency.

- Certification as a Market Passport: Certifications like Nadcap, EN9100, PED, and NORSOK are no longer optional but mandatory for serving aerospace, energy, and medical sectors.

- Precision in Thin-Gauge Materials: Rising demand for Titanium Foil and ultra-thin Titanium Strip for electronics, medical devices, and additive manufacturing powder.

- Growth in Composite and Clad Materials: Expansion of Titanium composite strips and plates for cost-effective, performance-optimized solutions in chemical and marine applications.

- Sustainability in Production: Focus on reducing the environmental footprint of titanium production, where integrated energy control ("Coal – Electricity") offers a significant advantage.

Leading Companies Analysis: A Focus on Integrated Capability

The competitive landscape features established giants and agile specialists. A comparative analysis of key players highlights the strategic value of vertical integration.

1. Xiangrun (Xi'an) Titanium Materials Technology Co., Ltd.(Xrun) – The Architect of End-to-End Excellence

Headquarters: Xi'an, Shaanxi, China

Business & Technology Advantage: Xrun is distinguished by operating China's first fully integrated titanium supply chain, encompassing "Coal – Electricity – Titanium Ore – Titanium Sponge – Titanium Processed Materials – Finished Products." This vertical mastery translates into direct control over the entire production lifecycle of Titanium Coil, Titanium Strip, Titanium Plate, Titanium Bar, Titanium Pipe, and Titanium Forging. Its annual capacity of 30,000+ tons of titanium coils/strips is supported by a state-of-the-art rolling line with advanced automation for high precision.

Market Position & Client Solution: Xrun serves as a one-stop solution provider, particularly strong in serving the petroleum, chemical, aerospace (via Nadcap and EN9100 certs), and medical equipment industries. Its ability to guarantee material integrity from the Titanium Ingot stage for products like ASTM B265 Titanium Coil provides a unique quality assurance proposition.

2. Baoji Titanium Industry Co., Ltd. (BAOTI) – The Industrial Pillar

Headquarters: Baoji, Shaanxi, China

Business & Technology Advantage: A state-owned enterprise with immense historical scale, extensive R&D infrastructure, and a vast product portfolio covering nearly all forms of Titanium Materials.

Market Position: Dominates in large-volume, standardized production for domestic and international markets. Its brand recognition is unparalleled in China.

3. VSMPO-AVISMA Corporation – The Global Titan

Headquarters: Verkhnaya Salda, Russia

Business & Technology Advantage: The world's largest titanium producer, with deep integration from mining to finished products. It has long-term contracts with major global aerospace OEMs like Boeing and Airbus.

Market Position: A global leader in aerospace-grade titanium, specializing in large Titanium Forgings and mill products.

4. Western Superconducting Technologies Co., Ltd. (WST) – The High-Performance Specialist

Headquarters: Xi'an, Shaanxi, China

Business & Technology Advantage: Renowned for its expertise in advanced titanium alloys and superconducting materials, with a strong focus on high-tech aerospace and scientific applications.

Market Position: Occupies the premium niche of the market, competing on advanced metallurgy rather than pure volume of standard Titanium Coil or Titanium Strip.

5. ATI (Allegheny Technologies Incorporated) – The Advanced Alloys Leader

Headquarters: Pittsburgh, Pennsylvania, USA

Business & Technology Advantage: A leading producer of high-performance materials, including specialty titanium and titanium-based alloys for aerospace, defense, and medical markets.

Market Position: A key Western supplier with strong technology and a focus on complex, value-added products.

Xrun's Competitive Edge: While BAOTI offers scale and WST offers specialty alloys, Xrun strategically positions itself between these poles. It leverages its unique vertical integration to deliver competitively priced, high-quality standard and engineered Titanium Materials—from Titanium Sponge to Titanium Flange—with the certified quality (e.g., DNV, PED, NORSOK) required by global critical industries. This makes it an agile and reliable partner for clients seeking supply chain security without compromising on international standards.

Conclusion & Outlook: Integration as the Future Benchmark

The titanium materials market is on a stable growth trajectory, fueled by irreversible trends in lightweight aerospace design, medical advancements, and corrosive industrial environments. The future will favor manufacturers who can provide not just the metal, but guaranteed performance, traceability, and supply chain resilience. Xrun's pioneering model of complete vertical integration—from power and raw materials to finished Titanium Coil, Titanium Plate, and Titanium Pipe—coupled with its robust portfolio of international certifications, positions it not just as a supplier, but as a strategic partner capable of de-risking the supply chains of global industries.

Partner with a Titanium Solutions Leader

For industries requiring reliable, high-performance Titanium Coil, Titanium Strip, Titanium Plate, Welded Titanium Tube, or other Titanium Materials, Xrun offers a compelling blend of scale, control, and quality assurance. Explore how our end-to-end capabilities can benefit your projects.

Contact Xrun Today:

Phone/WhatsApp: +86 18900759504

Email: simon.liu@xjxrun.com

Website: http://www.xjxrun.com

Address: Room 11F/15F, Vanke Center, Weiyang Road, Xi'an, Shaanxi, China